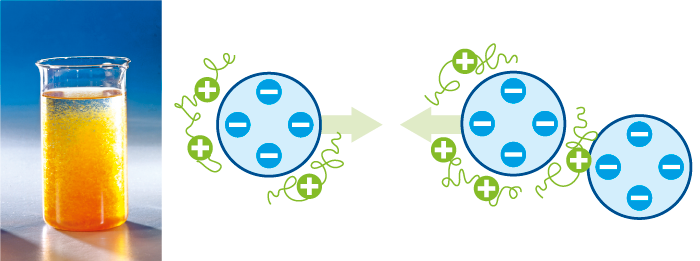

DEcomplexation

Separated chelated metals from detergents with DECOFLOC 777. Negatively charged particles after decomplexation.

Among the various solutions available to manufacturers to reduce their environmental impact, wastewater treatment is one of the most relevant. NGL specialists offer customized treatment plants according to the volumes of water to be treated, the types of effluents and the customer’s specific requirements.

See below an example of an industrial wastewater treatment plant in physicochemical processes (DECOFLOC).

The main pollutions : COD, BOD5, Phosphorus, SS, pH, heavy metals… are mostly removed by pH correction, filtration, decantation and coagulation/flocculation processes. When the COD at the treatment outlet exceeds 2000 mg/L, evapo-concentration systems are generally used.

Separated chelated metals from detergents with DECOFLOC 777. Negatively charged particles after decomplexation.

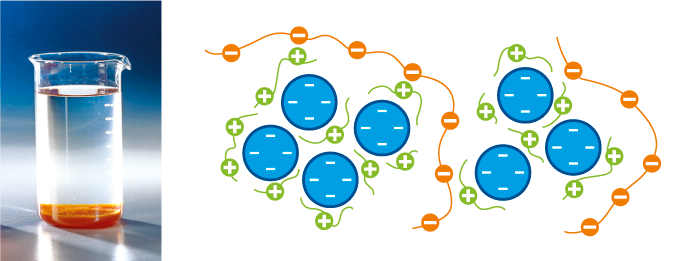

Agglomerate dissolved metals with coagulation salts with DECOFLOC 110. Particles are attracted after addition.

Agglomerate the molecules into flocs which mass and size allow decanting and filtering. Flocs are formed on a macroscopic scale.

Programming with probes and sensors to regulate all circuits. This type of automation also allows for remote control and easy operation through a touch screen.

For volumes up to 1m³ day, manual units can be set up. These installations are compact, easy to use and require no maintenance.

Turnkey treatment plant in a 20 feet container, including a reactor/decanter, a sludge tank, a filter press and the reagents allowing the insolubilization of the pollutions and the collection of the sludge. In addition, to avoid any nuisance, the system is completely isolated: frost-proof, silent, programmable: no nuisance and flexibility of use. Pre-assembled, this containerized station is installed in a few hours, set on the ground, for a capacity of 1 to 10 m³/day.

Download the NGL Product Data Sheet for your needs: