For many years, the ophthalmic industry has tried to replace glass blocking alloys with alternative techniques, because of its toxicity; nevertheless, it is still used in a certain number of applications.

Blocking alloy used for polishing organic lenses is a mixture of different metals: bismuth, lead, tin, cadmium and indium. Its melting point is 47°C, a relatively low temperature that allows it to be removed simply by soaking the alloy in hot water. Disposing of this polluted toxic wastewater is the difficult part.

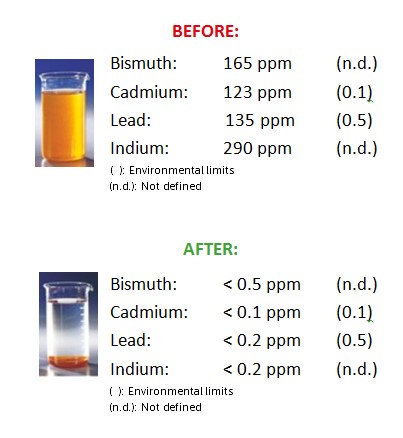

The concentration of these metals in the wastewater can reach hundreds of ppm, it is therefore highly toxic and must not be discharged into the sewerage. Instead, it is generally removed by specialized companies who handle the waste and dispose of it properly.

If the volume of the waste reaches a large enough volume, about a hundred litres per day, it can become economically interesting to treat it on-site by means of the Decofloc process for which the principle is shown in the scheme opposite

The metal content measurements below show the efficiency of the treatment:

The Decofloc process allows deblocking wastewater from glasses to be discharged in compliance with environmental standards.

For more details, please contact our water treatment division.