Used in the world of watchmaking, Epidrop No.3 is an epilam coating solution that contains a fluorinated compound that enables the reduction of surface tension. The very weak surface tension of the solvent and its great volatility mean that this product can be used in epilam coating.

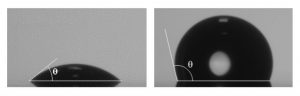

Before : After :

It can be applied with existing equipment: soaking, in an SAV machine (Greiner, Jema, Horotec) or in an industrial machine.

Key information:

- Compatible with all materials, especially efficient on rubies and steel

- Contact angle >65° with watchmaking oils used regularly on moving pieces

- Ready to use and simple to apply

- Resistant to multiple SAV washing

- Environmentally friendly

Preparation before epilam coating:

We would advise cleaning the pieces before epilam coating in order to prepare the surface. NGL products, Galvex 18.01, Galvex 20.01 and even Galvex 17.30 SUP enable better adhesion of the fluorinated polymer and improve the contact angle.

There should be no final rinsing with benzene or other hydrocarbon solvents; final rinsing should be with demineralised water, alcohol or Vertrel.

Technical and environmental data:

- Active material: fluorinated polyester

- Diluent: partially fluorinated solvent

- Density: 1.43 g/cm3

- Flammability point: non-inflammable

- Toxicity: non-toxic

- Does not damage ozone layer: 0 (ODP)

- Lifetime in atmosphere: less than 8 months

- Drying time: a few seconds

- Surface tension: c. 20 mN/m

- Polymer stability: up to 150°

Example of hybrid procedure: (top of range finishing and metals sensitive to corrosion)

If you have any questions, please contact our Application Centre on :

+41 22 365 46 66