Laser engraving is one of the key stages in the manufacture of luxury goods. It can be used to personalize the piece, to indicate the manufacturer’s brand, a reference number, or simply to add decorative elements.

However, this stage is not without its problems, particularly for steel and brass. A number of physical and chemical phenomena occur, resulting in black metal discoloration on copper and ferrous metals.

Under the effect of the laser beam, the local temperature can reach 500-800°C, generating the formation of oxides:

– For brasses, copper oxidizes to CuO, which is highly stable.

– For steels, the oxide that forms is Fe₃O₄, which is stable and highly adherent.

These oxides are difficult to remove chemically. What’s more, the material vaporized during laser impact partially recondenses into fine black particles (metallic fumes, oxides), which are deposited in and around the engraved area, in the form of slag. Finally, the local melting of the material creates a rough surface that enhances the adhesion of oxides.

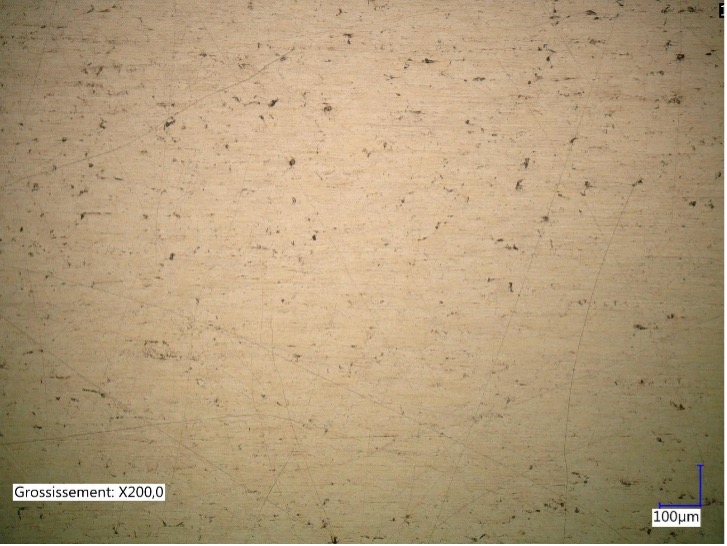

Deoxidation of laser engraving on stainless steel parts with RODASTEL 30 :

Optimizing laser parameters is also an important factor in limiting damage caused during engraving.

What chemicals can be used to strip these different oxides?

Deoxidation is traditionally carried out in an acidic environment. However, care must be taken when selecting the acid used.

Strong acids such as hydrochloric acid, nitric acid and sulfuric acid should be avoided for the following reasons:

– Operator safety risks associated with handling these highly corrosive substances.

– Risk of oxidation of parts, irreversible damage such as corrosion pitting that may form.

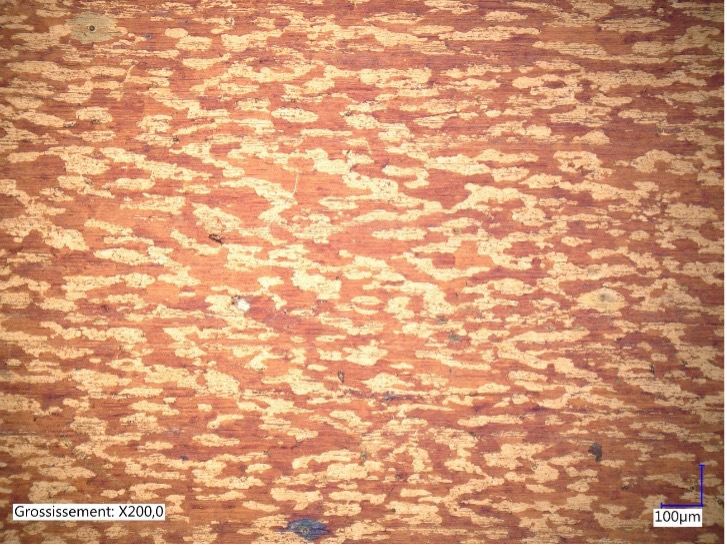

– More specifically, on brass, over-aggressive pickling can lead to zinc removal. Damage can range from revealing the alloy’s microstructure to complete oxidation of the surface, giving brass a brown or reddish appearance.

Surface oxidation of a lead-free brass part following use of an unsuitable product:

So what’s the best solution for stripping parts?

Specialists like NGL CLEANING TECHNOLOGY are able to offer you the best compromise between efficiency and safety. Our products, such as CERACLEAN SP 2022, RODASTEL 30 and SOLVIT N°4, are subtle blends of aggressive and mild chemicals and corrosion inhibitors, dosed to achieve maximum effectiveness with minimum risk to health and the environment.

The mechanical action of ultrasound, generally 40 kHz, maximizes the effect of the chemistry and enables in-depth cleaning of oxides, without altering the part itself, even on mirror-polished finishes.

Call on NGL for perfect cleaning of your laser engravings.