The main pollutants : COD, BOD5, Nitrogen, Phosphorus, suspended solids, pH, heavy metals… are largely removed by the pH correction, coagulation/flocculation, decantation and filtration stages. Precious substances present in the water can also be recovered up to 95%.

Where residual COD is too high (hard COD), or peristant pollutants such as cyanides are present, post-treatment systems such as activated carbon, advanced oxidation or evapo-concentration complete the process.

Among the various solutions available to industrial companies to reduce their environmental impact, wastewater treatment is one of the most relevant. Besides wastewater treatment (industrial WWTP), improving quality of process waters and recycling them are great solutions for manufacturing sites aiming at decreasing their water consumption while improving there processes.

NGL’s specialists offer treatment plants tailored to the volume of water to be treated, the type of effluent and the customer’s constraints, enabling them to reduce their environmental impact.

Decofloc physicochemical stations

Decofloc chemical products

- DEcomplexation: Separate metals from detergents with Decofloc 777. See the product

- COagulation: Agglomerate particles with metal salts using Decofloc 110. Particles attract each other after the addition of coagulant. See product

- FLOCulant: Agglomerate particles into flocs of a mass and size that can be decanted and filtered with Decofloc HBV. See the product

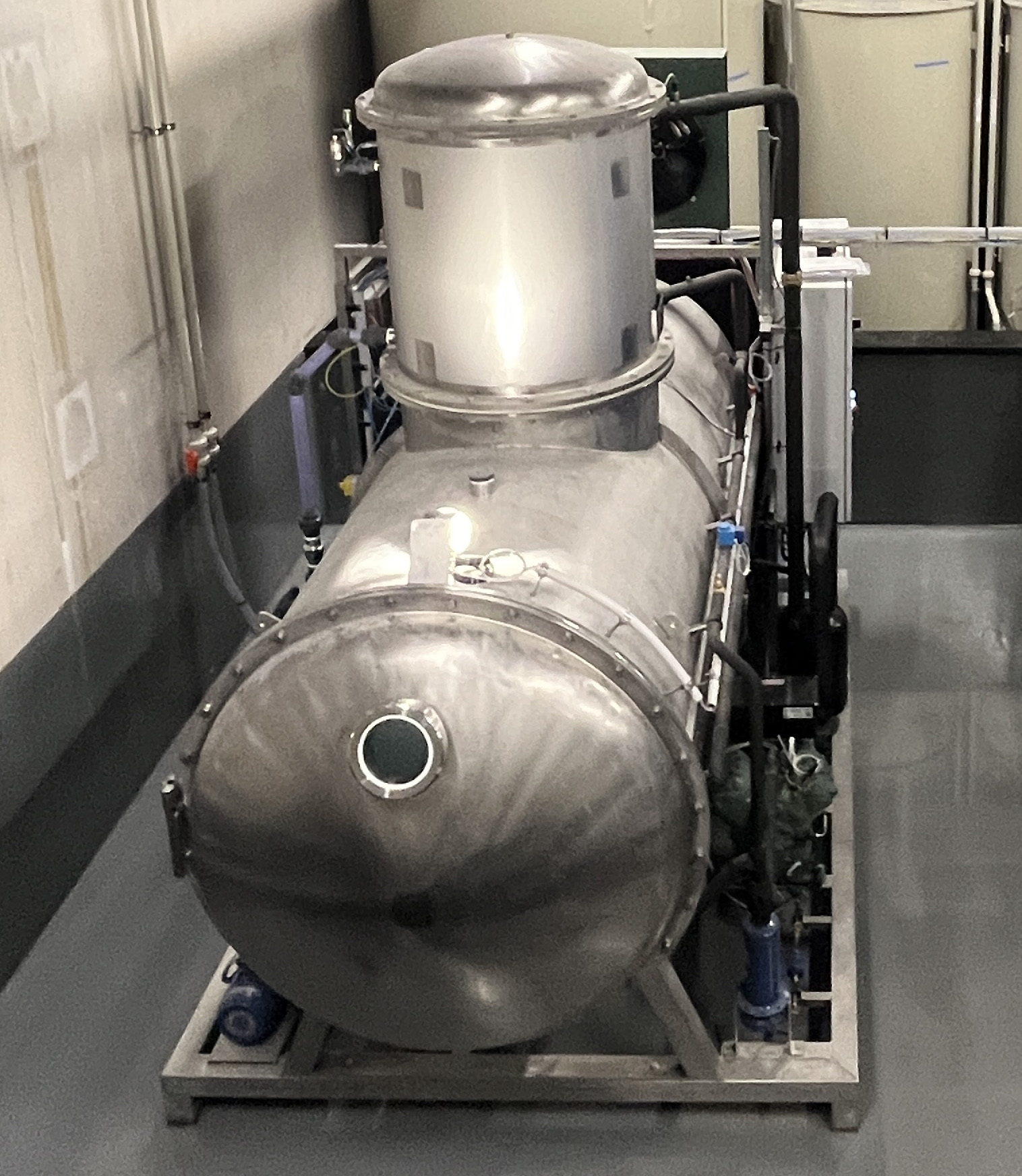

Evaporators

Separation of the aqueous phase from the process pollutants by distillation, which takes place in a boiler maintained under vacuum to bring the solution to the boiling point at a temperature of 35 to 38°C. The distillate obtained has similar characteristics to demineralised water and can therefore be reused in the production process. Vacuum evaporators allow around 90-95% of treated wastewater to be recovered in distillate form.

Container

Turnkey treatment plant in a 20-foot container, comprising a reactor, sludge tank, filter press and reagents for insolubilising pollutants and recovering sludge. What’s more, to avoid any nuisance, the system is completely insulated: frost-free, silent, programmable, no nuisance and flexible to use. Assembled in advance, this containerised plant can be installed in just a few hours, on the ground, with a capacity of 1 to 10 m³/day.

Advanced oxidation

Hard COD is the most difficult fraction to biodegrade and is resistant to biological treatment. It is made up of complex organic substances.

Treatment using the UV + H2O2 process eliminates these persistent and bioaccumulable organic residues by oxidation until the pollutants are completely mineralised in the form of carbon dioxide and water.