Customized cleaning methods for your parts

A constraint, a solution

In industry, regardless of the field of activity, the choice of cleaning method is crucial.

Ultrasonic or spray cleaning is generally preferred, but in recent years, vacuum cleaning has emerged as a third relevant solution, particularly for medical devices and electronics.

Many sectors benefit from hybrid solutions that combine several methods to achieve the best possible result.

The choice depends on a multitude of factors. Our experts will help you choose based on:

- The geometry and size of the parts

- The type of materials and contaminants

- The expected yield

- Budget constraints

- Environmental requirements

Solvent or detergent?

BOTH!

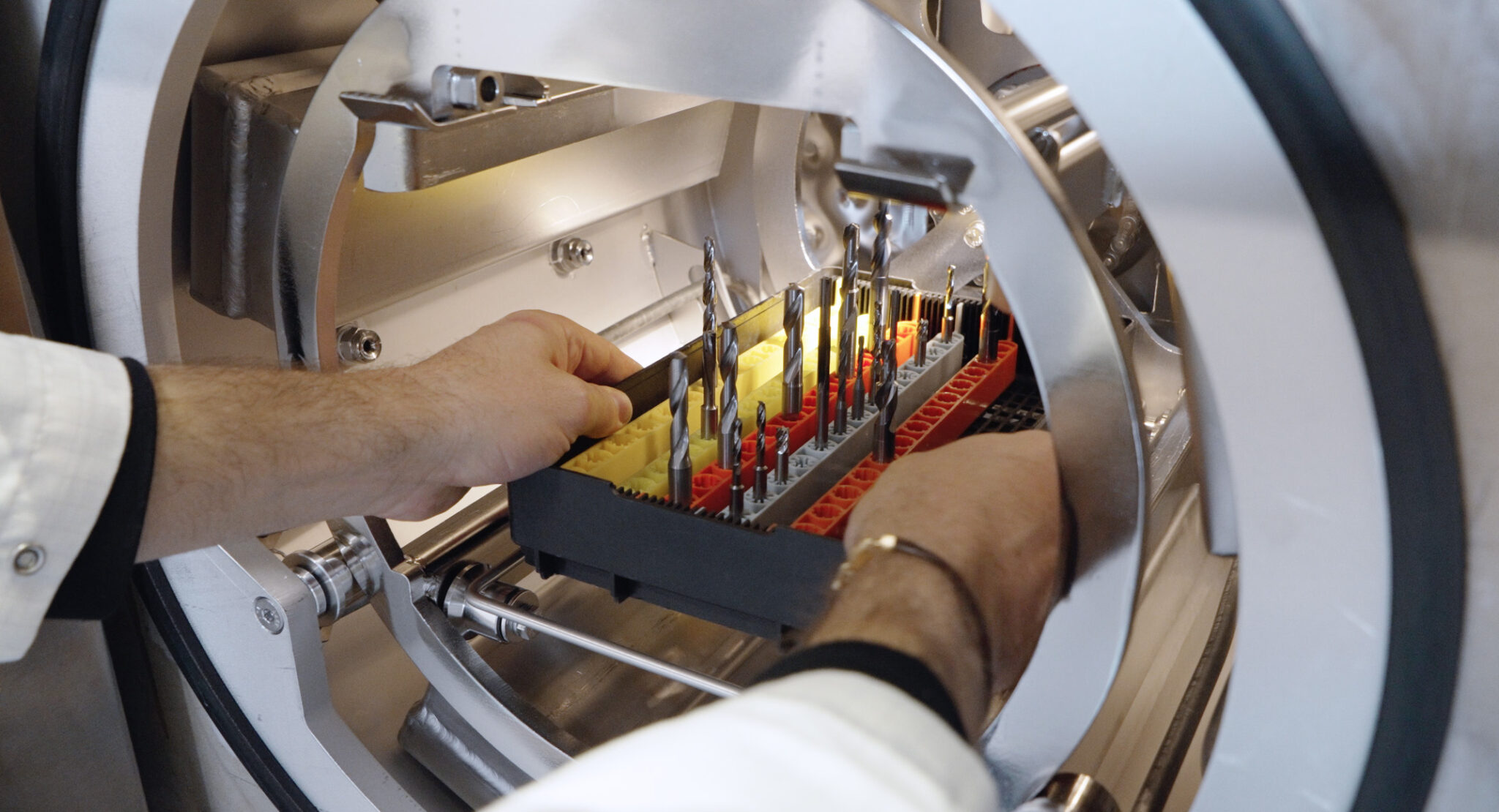

Solvent technologies are suitable for removing non-polar contaminants, such as cutting oils, when there is no water on the parts. Cleaning is generally carried out in a vacuum chamber, allowing for the effective cleaning of bulk parts and/or parts with complex geometries.

However, when polar, aqueous, or mineral contaminants are present, detergent solutions offer an advantage and can be applied either by immersion with ultrasound or by spraying.

Questions fréquentes

Which parts are best suited for ultrasonic cleaning?

Ultrasonic processes offer unmatched versatility. This is thanks to the flexibility in the number of cleaning or rinsing tanks, the type of water used (hard, softened, demineralized, osmosis water), and even the type of ultrasound present in the tanks.

Depending on the configuration of the line, several types of parts (small parts or parts with complex geometries), materials, and contaminants can be cleaned at high speeds.

When is spray cleaning more effective?

Spray cleaning offers high throughput rates and is suitable for uniform, flat parts that are large in size or processed in large batches (e.g., machined parts, trays).

Ideal for removing dust, grease, and other contaminants.

When should vacuum cleaning be used?

Vacuum cleaning gets the most out of ultrasonic cleaning, while allowing you to clean parts in the deepest crevices.

Examples: Cannulas, syringes, nozzle cutters, watch bracelet links, orthopedic implants with concave elements and blind holes, eyeglass hinges, etc.

Request for quotation and information