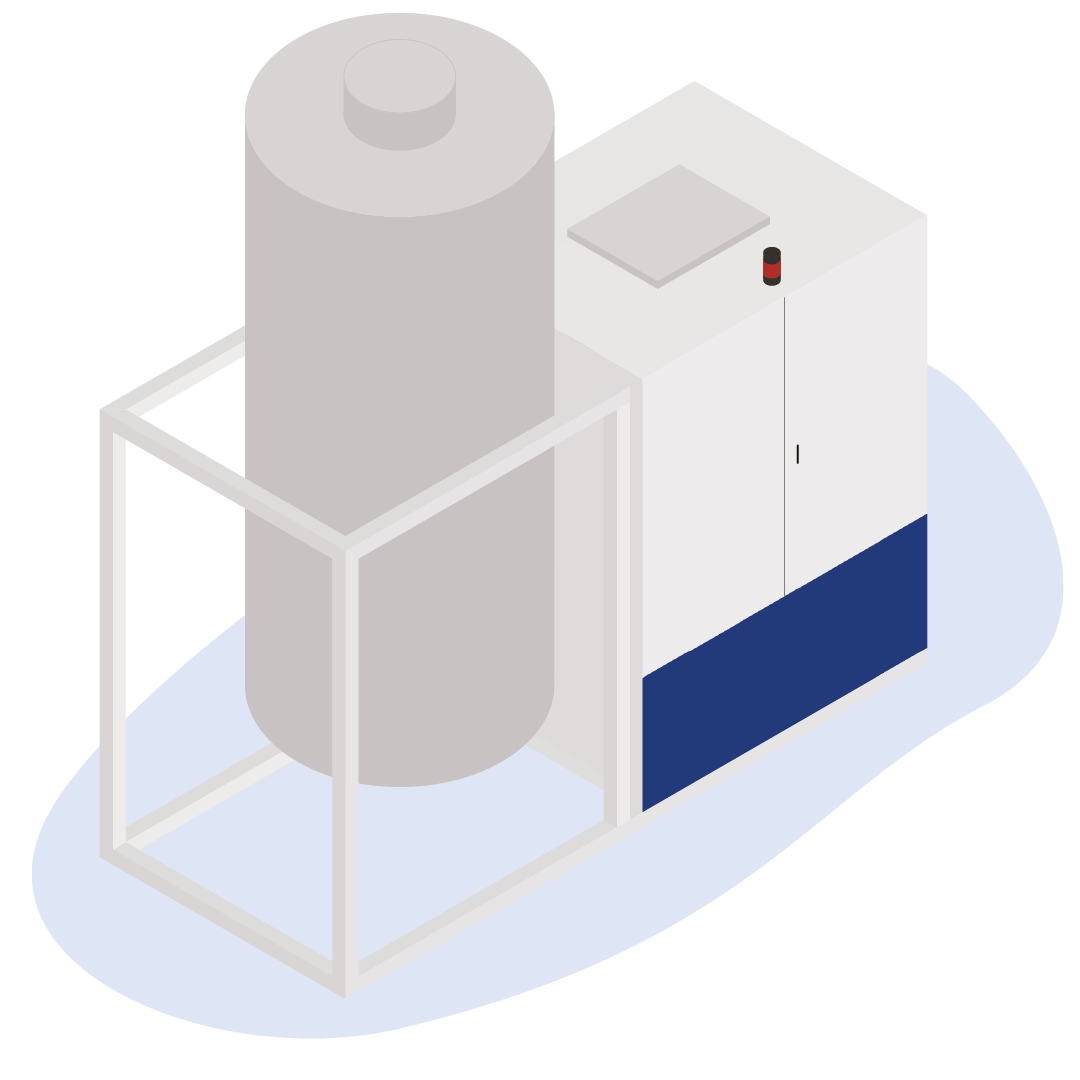

EVAPO CONCENTRATOR

- CVD Evaporator (with scraper, flow rate: 15–100 l/h)

- EV Evaporator (without scraper, flow rate: 15–400 l/h)

Request a quote

Challenges

■ Recovery of precious metals (Gold, Palladium, etc...)

■ Compliance of industrial water discharges

■ Zero Liquid Discharge

■ Reduction in water consumption

■ Process water recycling

■ CSR approach (Corporate Social Responsibility)

Types of water to be treated

■ Tribofinishing

■ Cleaning line: used baths and rinsing water

■ Hand-washing water (containing precious material particles)

■ Electroplating workshop effluents

Elements to be treated

■ Metals: Copper, Gold, Silver, Nickel, Palladium, etc...

■ pH

■ Chemical Oxygen Demand (COD)

■ Cyanides

■ Hydrocarbons, emulsions

■ Suspended Solids: gemstone residues...

Challenges

■ Recovery of precious metals (Gold, Palladium, etc...)

■ Compliance of industrial water discharges

■ Zero Liquid Discharge

■ Reduction in water consumption

■ Process water recycling

■ CSR approach (Corporate Social Responsibility)

Types of water to be treated

■ Tribofinishing

■ Cleaning line: used baths and rinsing water

■ Hand-washing water (containing precious material particles)

■ Electroplating workshop effluents

■ Polishing and lapping water

Elements to be treated

■ Metals: Copper, Gold, Silver, Nickel, Palladium, etc.

■ pH

■ Chemical Oxygen Demand (COD)

■ Hydrocarbons, emulsions

■ Suspended Solids: gemstone residues...

Challenges

■ Recovery of precious metals (Gold, Palladium, etc...)

■ Compliance of industrial water discharges

■ Zero Liquid Discharge

■ Reduction in water consumption

■ Process water recycling

■ CSR approach (Corporate Social Responsibility)

Types of water to be treated

■ Tribofinishing

■ Cleaning line: used baths and rinsing water

■ Hand-washing water (containing precious material particles)

■ Electroplating workshop effluents

■ Polishing and lapping water

Elements to be treated

■ Metals: Copper, Gold, Silver, Nickel, Palladium, etc.

■ pH

■ Chemical Oxygen Demand (COD)

■ Cyanides

■ Hydrocarbons, emulsions

Challenges

■ Recovery of precious metals (Gold, Palladium, etc...)

■ Compliance of industrial water discharges

■ Zero Liquid Discharge

■ Reduction in water consumption

■ Process water recycling

■ CSR approach (Corporate Social Responsibility)

Types of water to be treated

■ Tribofinishing

■ Cleaning line: used baths and rinsing water

■ Hand-washing water (containing precious material particles)

■ Electroplating workshop effluents

■ Polishing and lapping water

Elements to be treated

■ Metals: Copper, Gold, Silver, Nickel, Palladium, etc...

■ pH

■ Chemical Oxygen Demand (COD)

■ Cyanides

■ Hydrocarbons, emulsions

Challenges

■ Mise en conformité des rejets d'eaux industrielles

■ Zéro Rejet Liquide

■ Baisse de la consommation en eau

■ Recyclage eaux de process

■ Démarche RSE

Types of water to be treated

■ Tribofinishing

■ Electropolishing

■ Anodizing

■ Cleaning line: used baths and rinsing water

■ Polishing paste

■ Passivation

■ Polishing and lapping water

Elements to be treated

■ Metals: Copper, Nickel, etc...

■ pH

■ Chemical Oxygen Demand (COD)

■ Hydrocarbons, emulsions

Challenges

■ Récupération des métaux précieux (Or, Palladium, etc. ..)

■ Mise en conformité des rejets d'eaux industrielles

■ Zéro Rejet Liquide

■ Baisse de la consommation en eau

■ Recyclage des eaux de process

■ Démarche RSE

Types of water to be treated

■ Tribofinishing

■ Cleaning line: used baths and rinsing water

■ Acid pickling

■ Heat treatment

■ Polishing and lapping water

Elements to be treated

■ Metals: Copper, Nickel, Gold, Zinc, etc.

■ pH

■ Chemical Oxygen Demand (COD)

■ Cyanides

■ Hydrocarbons, emulsions

More information

Need a quote or a study?

Appears in

Why NGL?

Quality

Quality is at the heart of our approach, whether in production, product development or the services we provide. Whether for luxury goods or technical applications, our customers’ parts are often made of fragile materials and undergo numerous manufacturing stages. The quality of our products guarantees their effectiveness and compatibility with the materials being processed.

Reliability

Aware that productivity is an integral part of any plant, NGL is also committed to ensuring flawless supply. By diversifying our sources of supply, we ensure the availability of our raw materials; by our safety culture, we avoid the risk of accidents and breakdowns at our production sites; and by our mastery of logistics, we ensure that our products can be delivered anywhere in the world, safely and in compliance with international regulations.

Expertise

Luxury, technology, eyewear, cutting tools, NGL has developed expertise in each of these fields, covering both materials and pollution. Whether for polishing, cleaning, decoating or water treatment, our experts put their know-how at your disposal. Do not hesitate to test our knowledge by requesting a trial run. We learn from our customers.